Ultrashort Pulse Laser Ablation

The energy of a focused laser beam can be used to remove material by so called ablation processes. With ultrashort laser pulses the energy is delivered in such a short time that ablation takes place before heat conduction to the bulk material. As a result ultrashort laser pulses can be used to process materials without thermally affecting the surrounding bulk material. This can be used to machine materials more precisely with much less heat-related negative effects. A second advantage of ultrashort pulse processing is that practically any material can be processed. This is caused by the extremely high energy densities that allow for multi-photon absorption. Materials that are transparent to the laser wavelength can still be processed.

Laser Micromachining

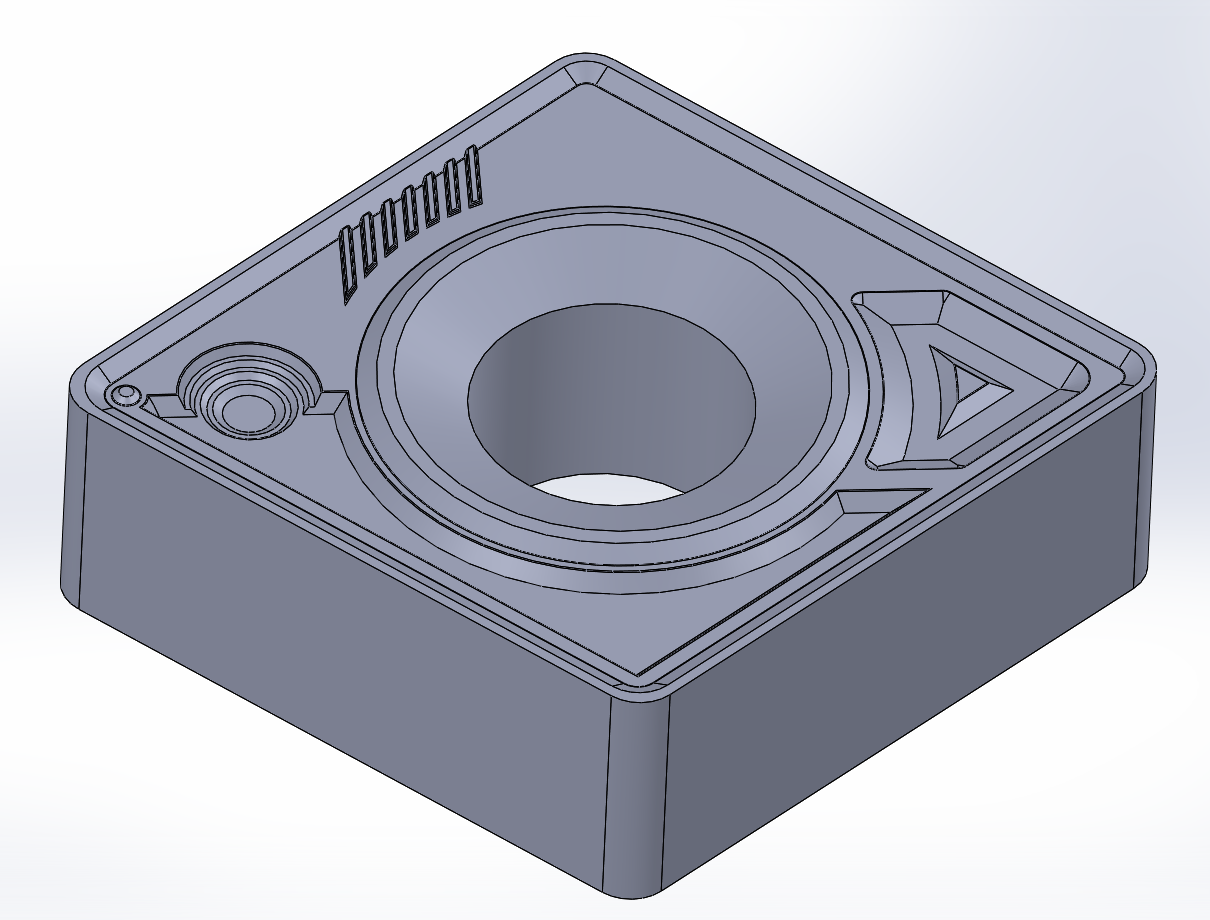

A single ultrashort laser pulse influences an area of approximately the size of the laser spot with a typical diameter between 10 and 30 micrometer. Depending on the material and pulse energy a single pulse removes between a few nanometers up to a micrometer of depth. To be able to process an area and create specific structures laser scanning is used to rapidly move the focused laser beam over the workpiece. For working on larger / curved parts the surface is divided into tiles and a multi-axis motion system is used to position the laser scanner over each tile for processing. This step-and-scan laser micromachining is fast and accurate: the use of the scanner allows fast manipulation of the laser spot; and because the larger motion system does not need to move during the actual processing it can maintain its position very accurately.

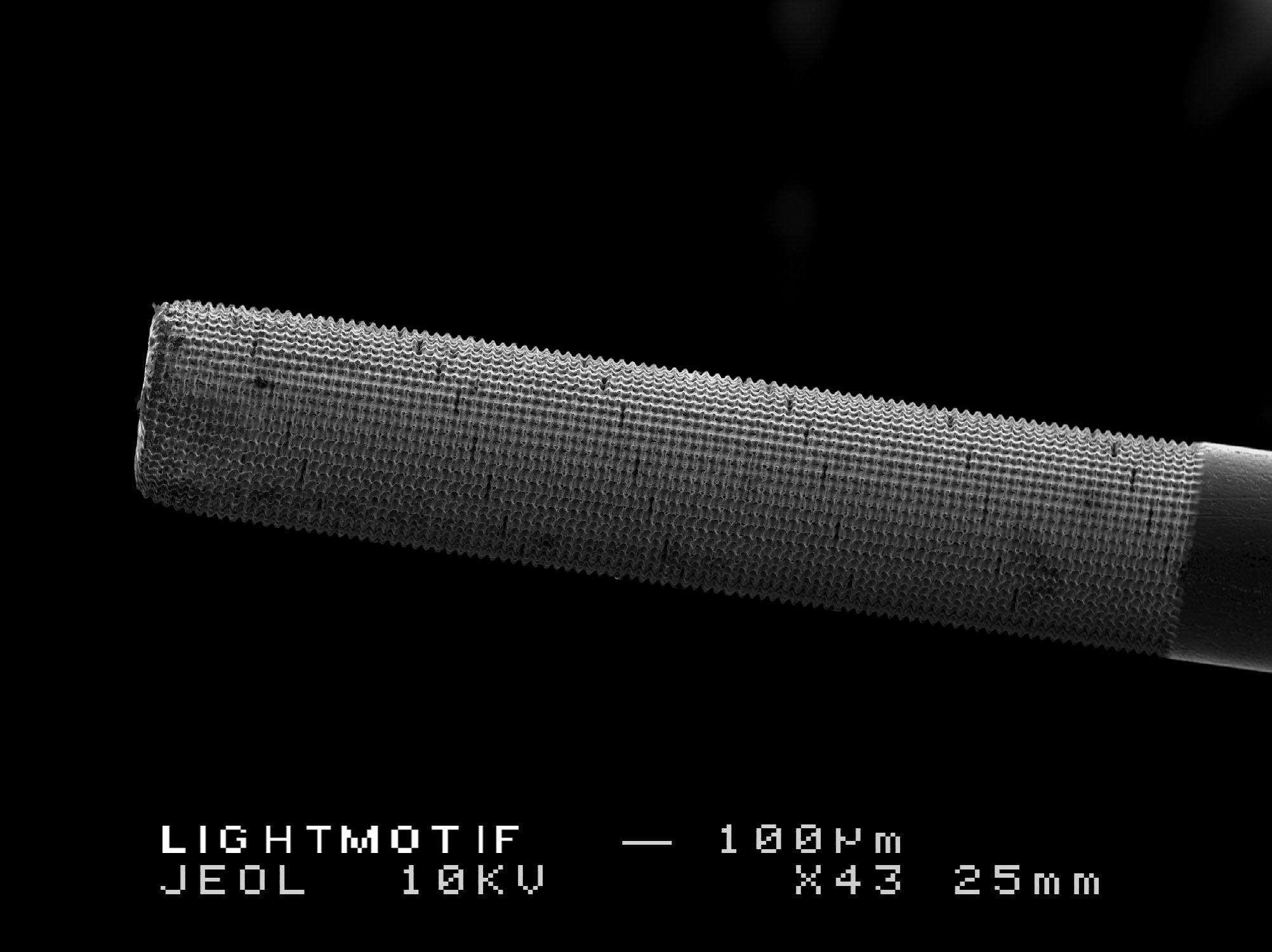

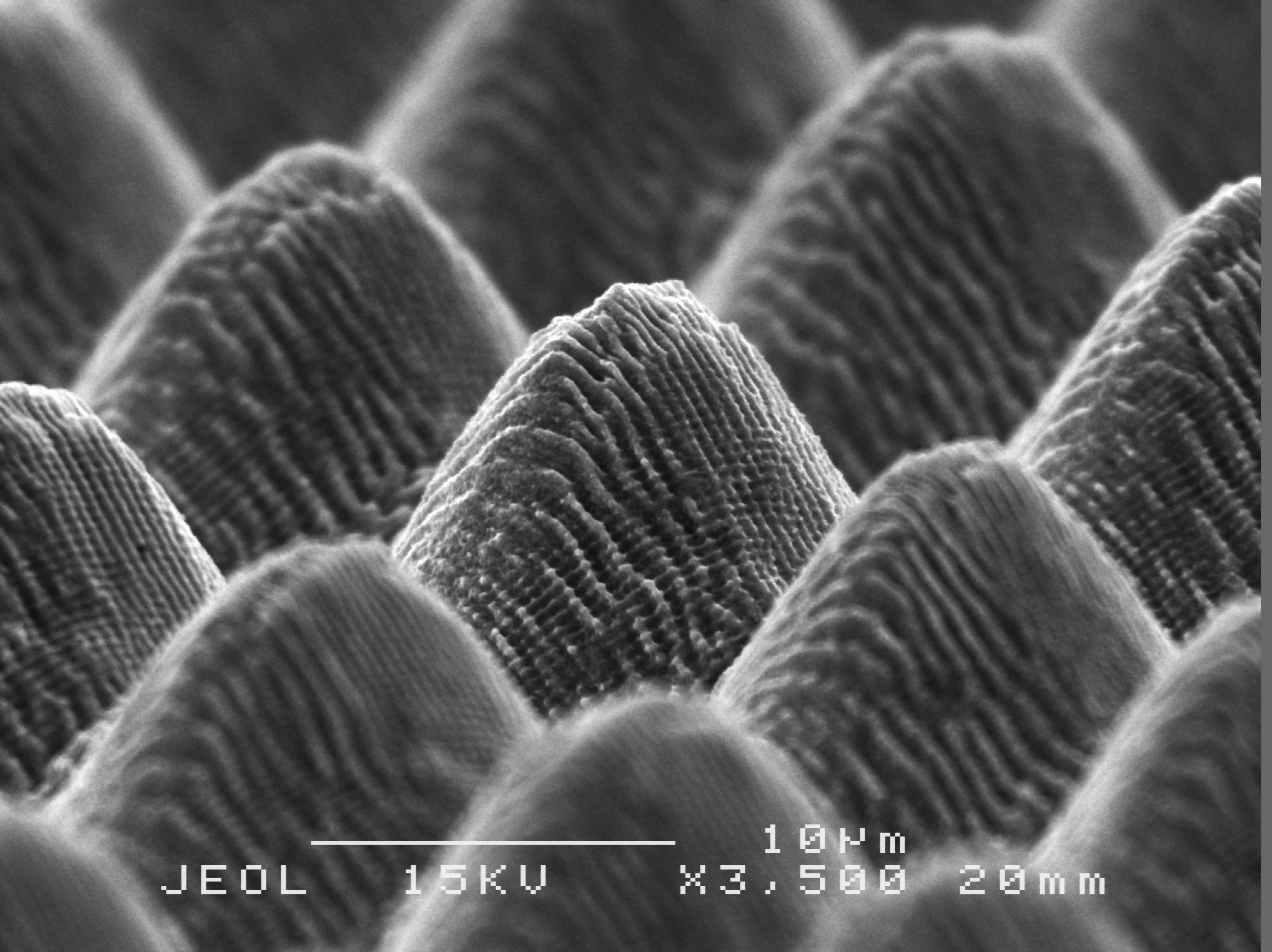

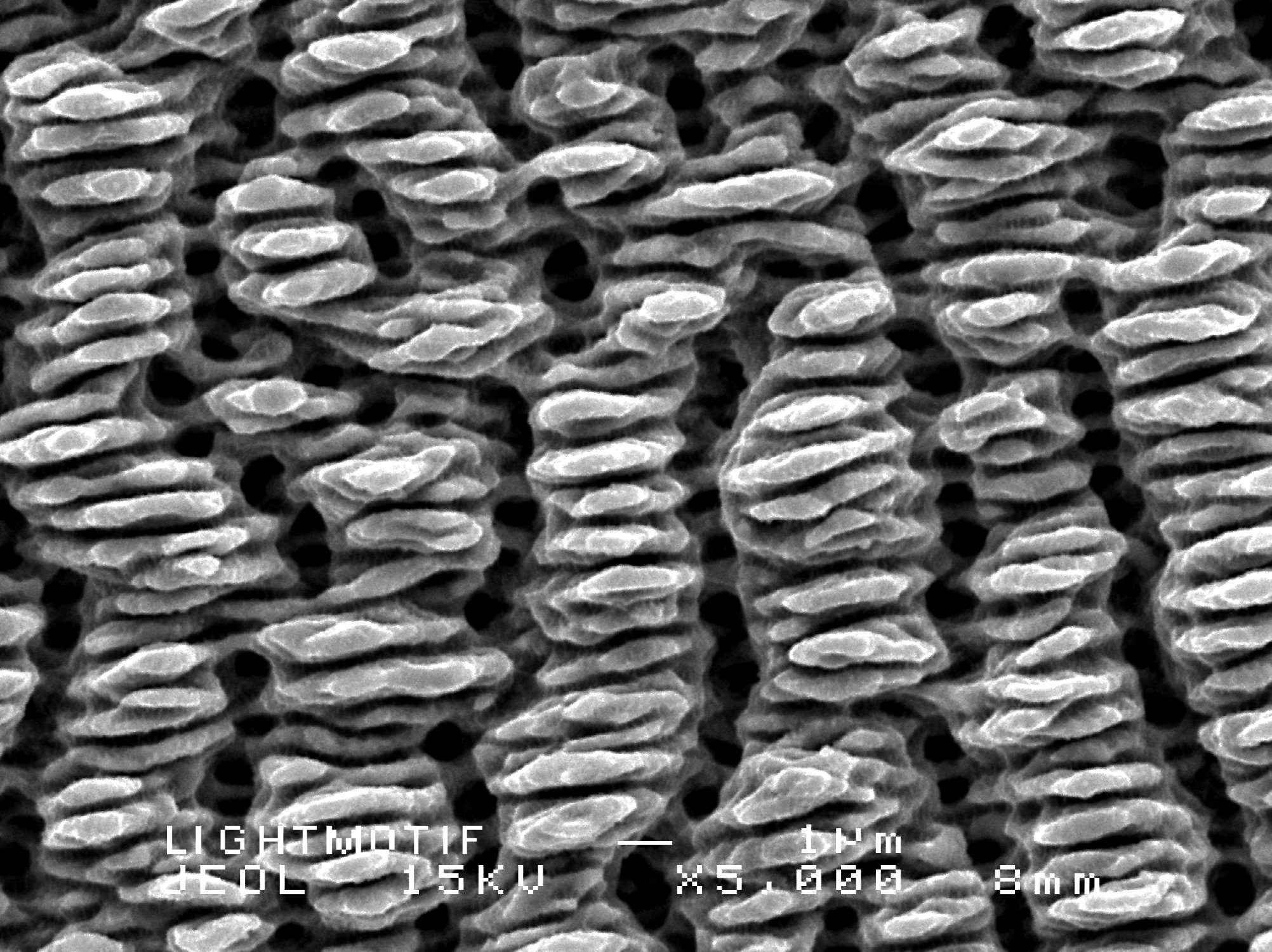

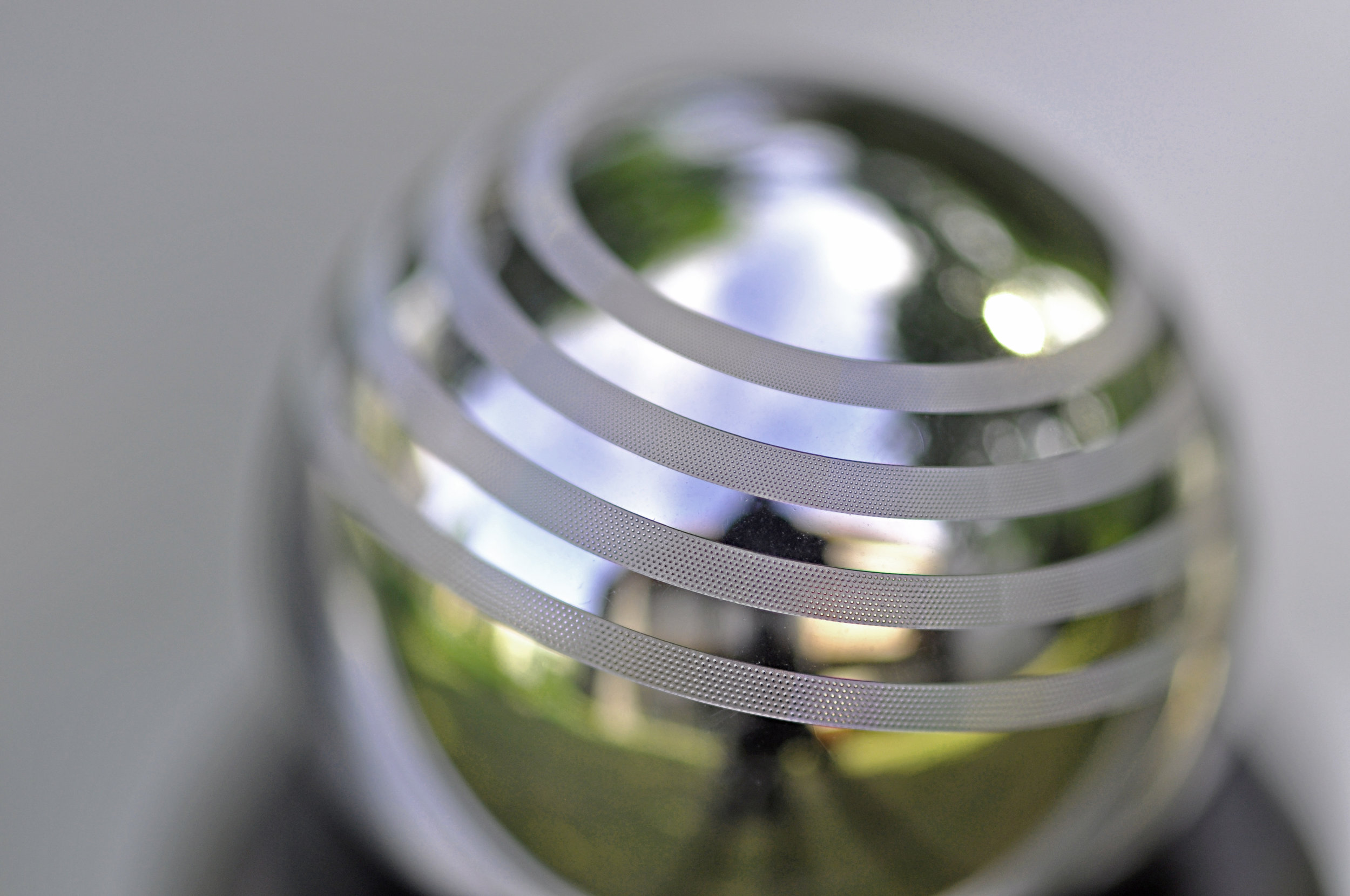

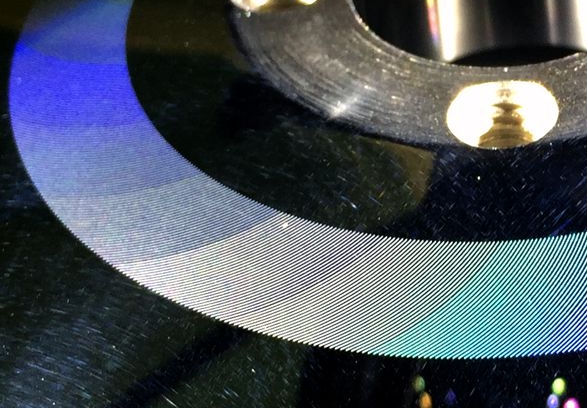

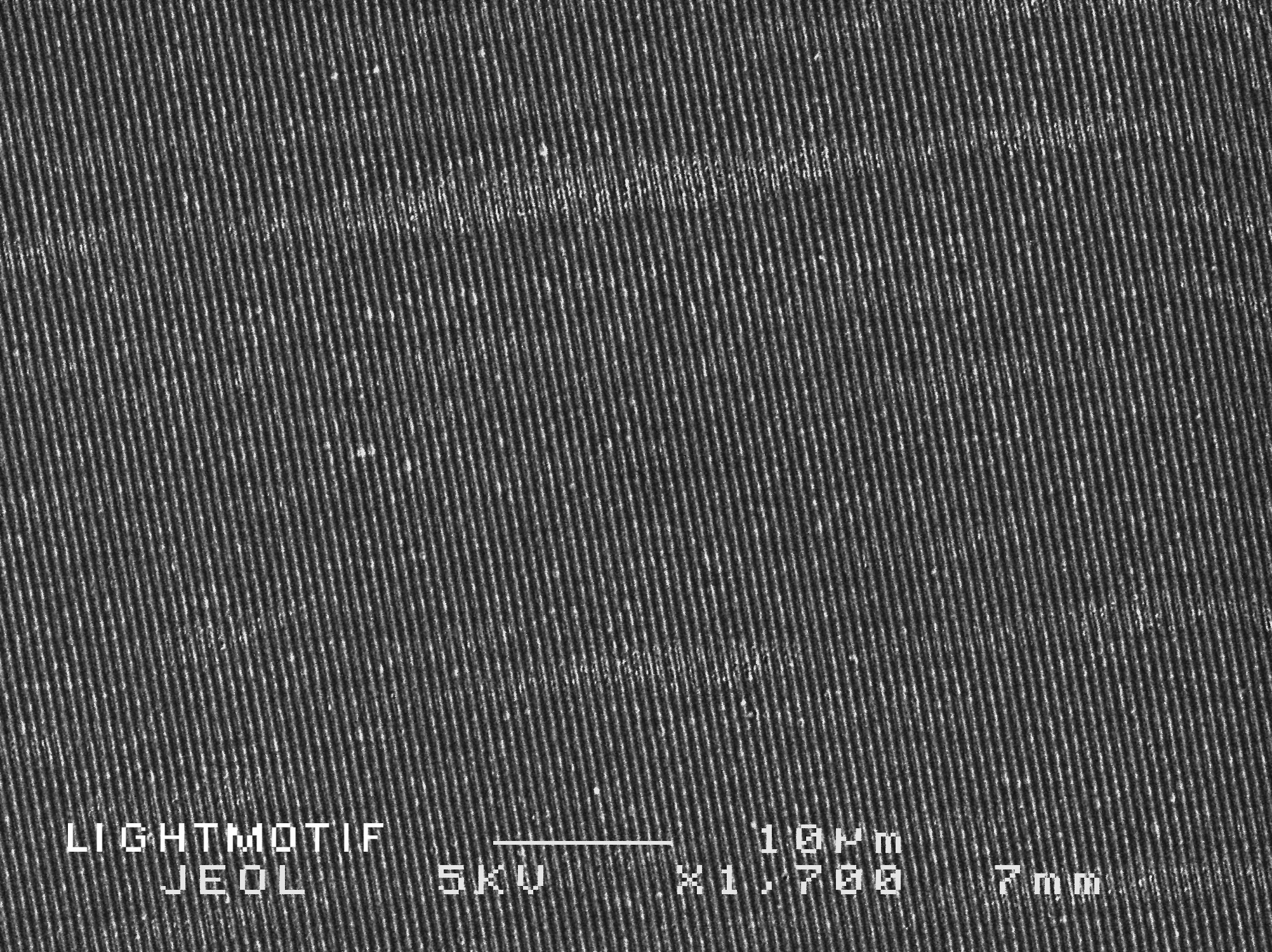

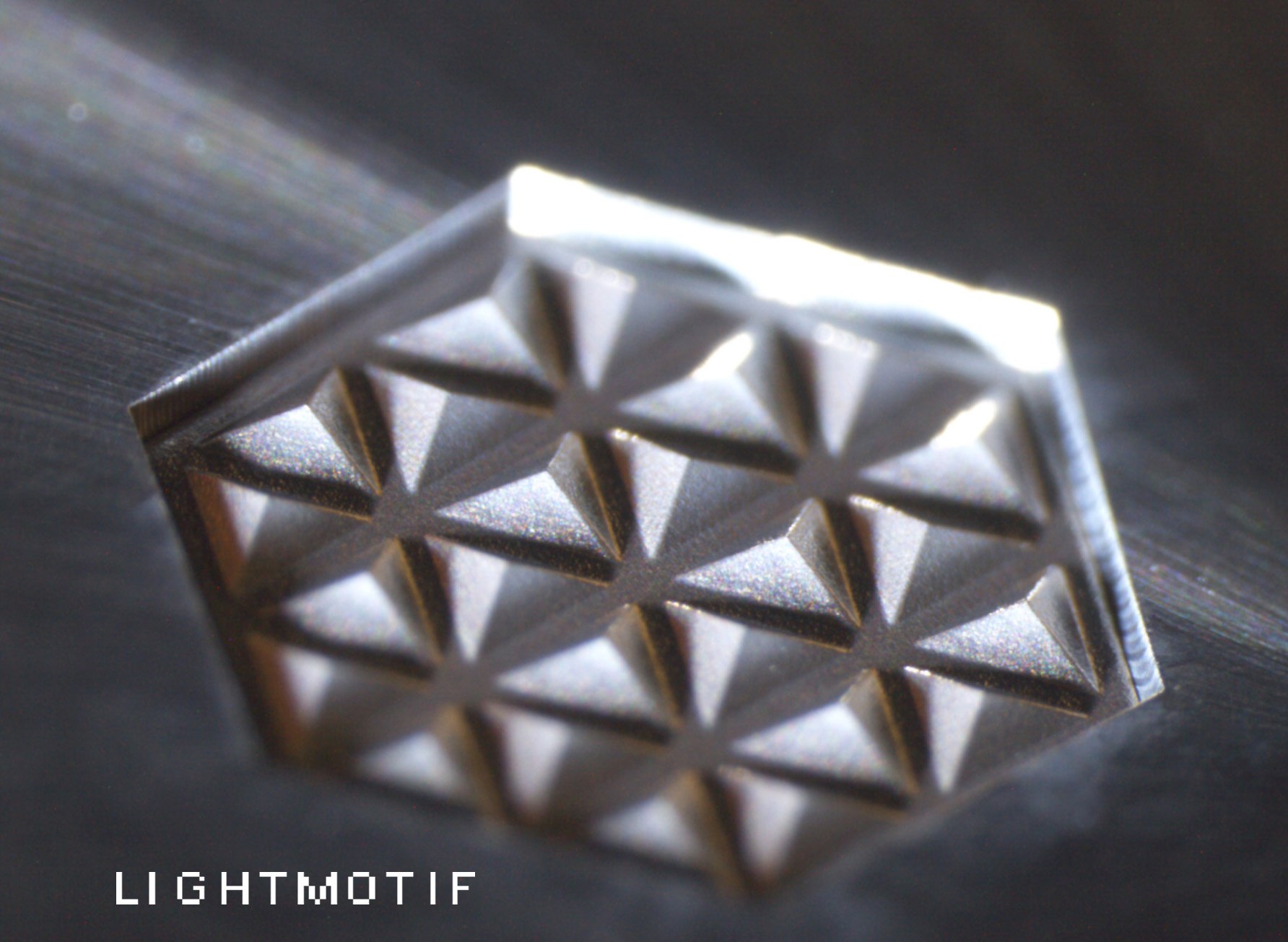

Laser surface texturing

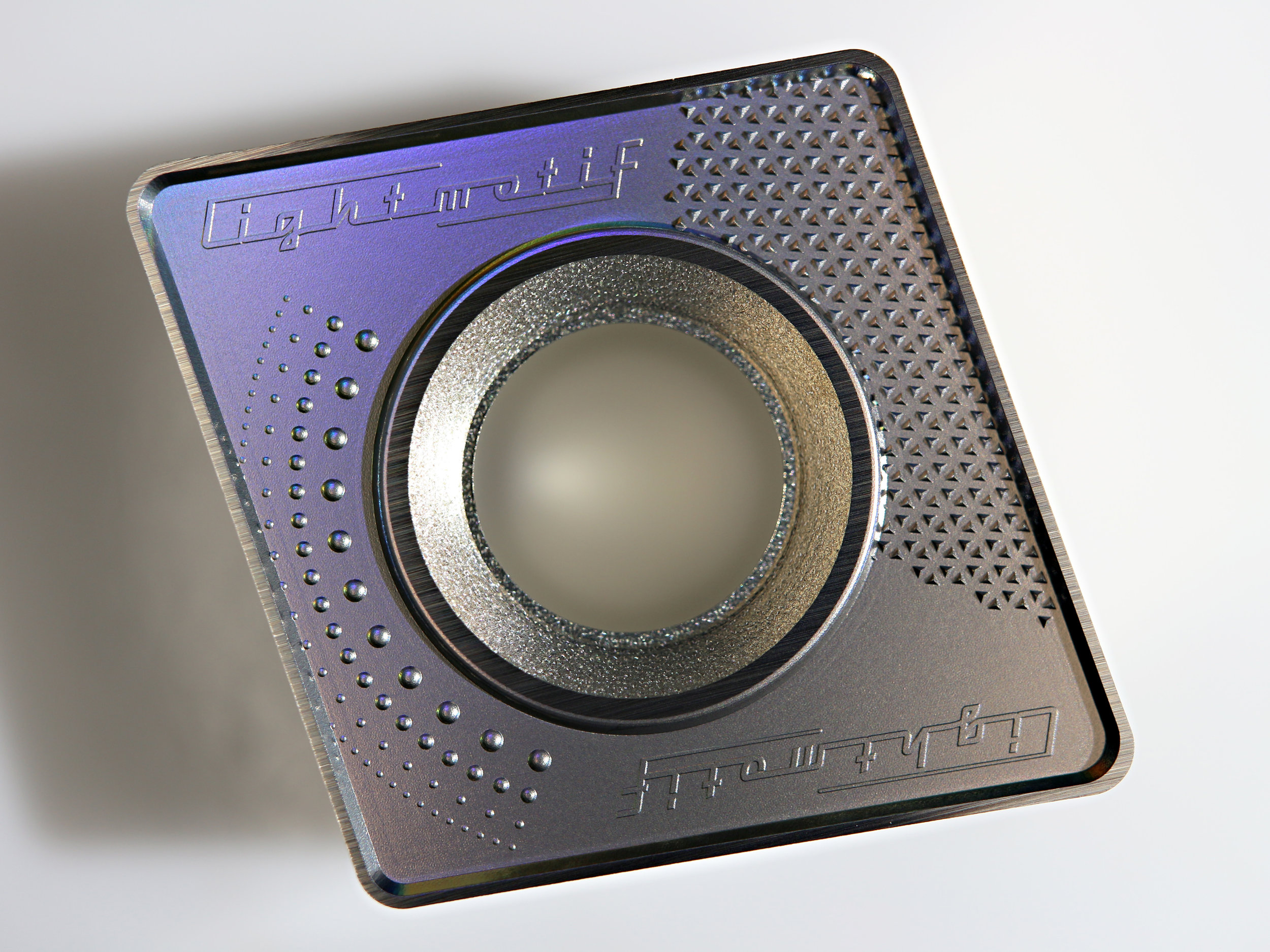

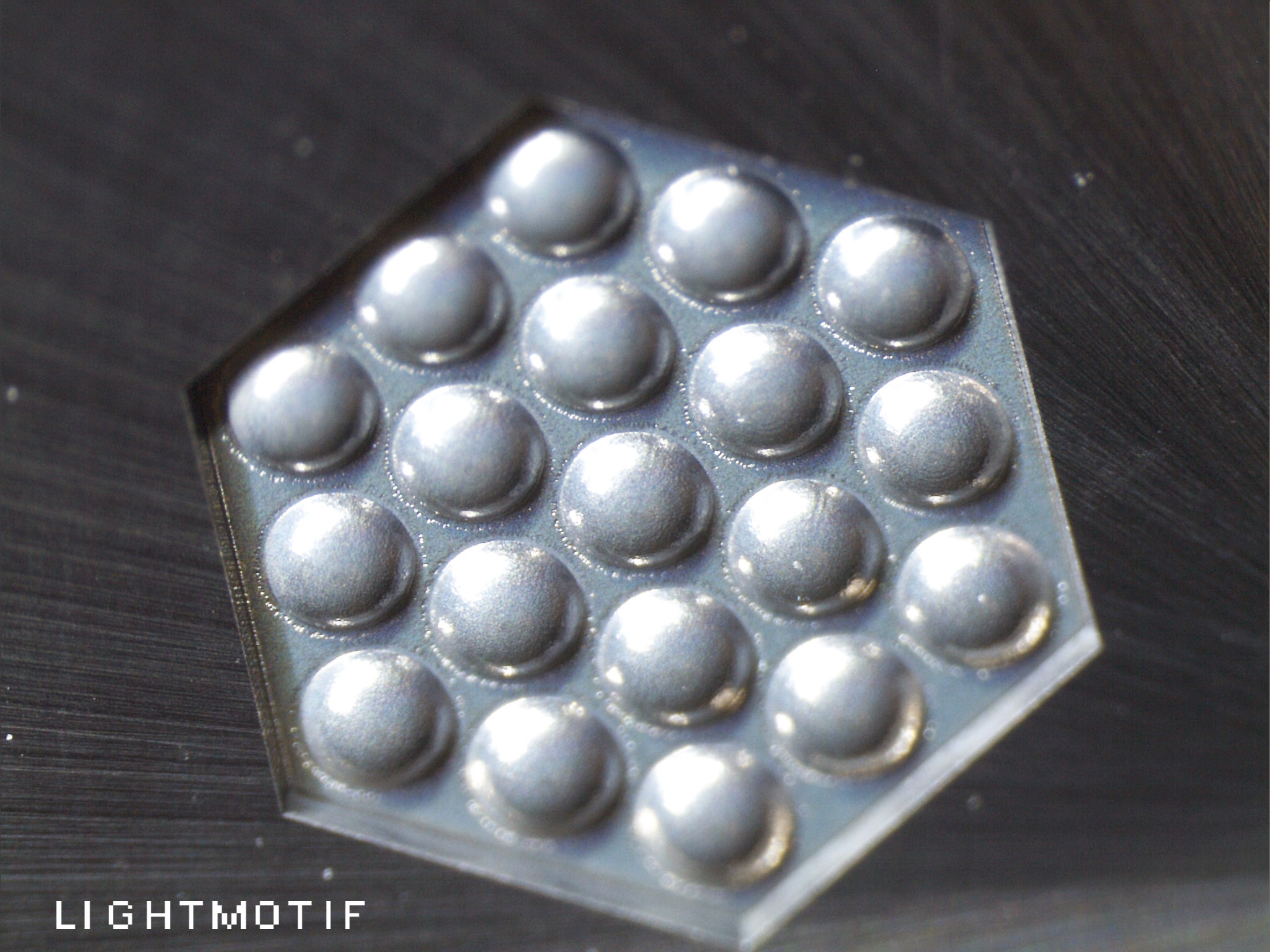

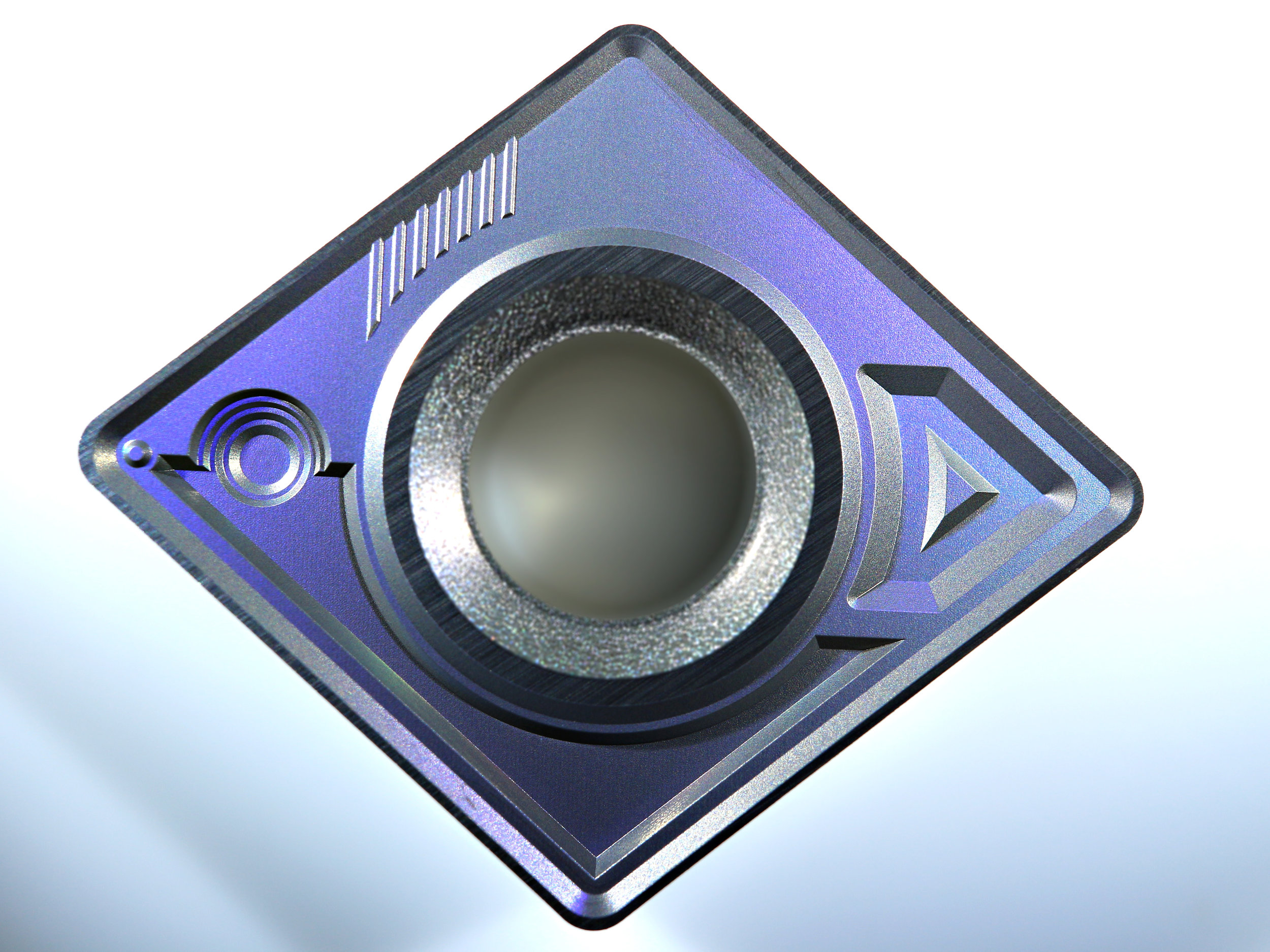

Laser micro-texturing using ultrashort pulse lasers is a new technology for applying surface textures with very fine features and an extremely high depth resolution. It allows the creation of small-scale textures that change the functional properties of surfaces, like reduction of friction or change of optical properties. The process can be applied on any material and can be used for texturing complex curved surfaces.

Laser micro-milling

Laser micro-milling using ultrashort pulse lasers makes it possible to machine accurately shaped structures with very small features into nearly any material. The process allows removal of extremely thin layers and is especially interesting for machining of very hard materials and delicate parts.

Cutting

Laser cutting using ultrashort pulse lasers can create highly accurate cuts with exceptional quality and little or no damage to the surrounding material. Since no mechanical forces are applied this cutting method is ideal for delicate materials or thin foils. The required kerf width can be as small as the focused laser spot, which is typically 10–30 μm. Hard and brittle materials like glass or ceramics can be cut without cracks or chipping. Due to the very low heat input, even composites with large differences in thermal properties can be machined.

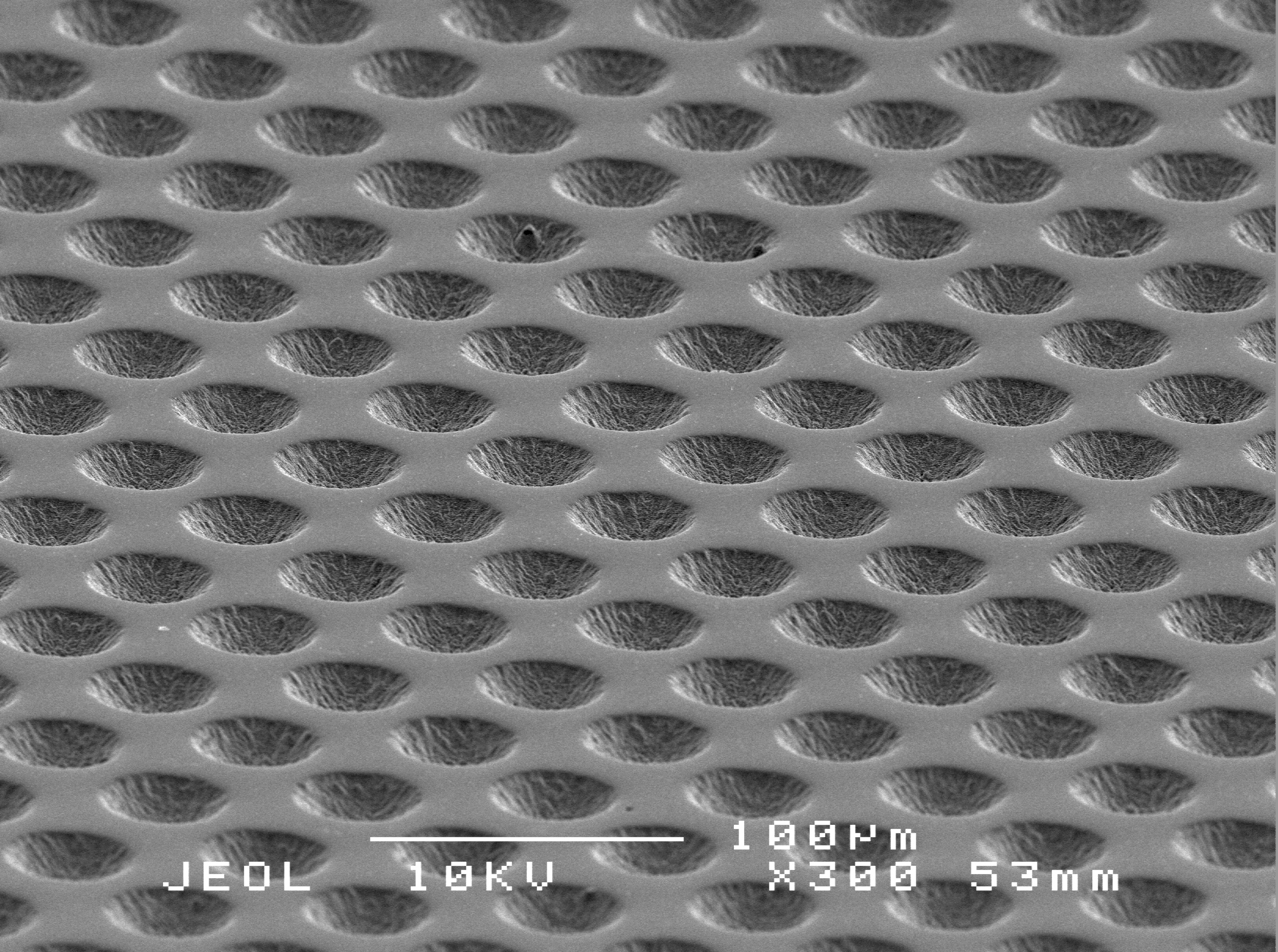

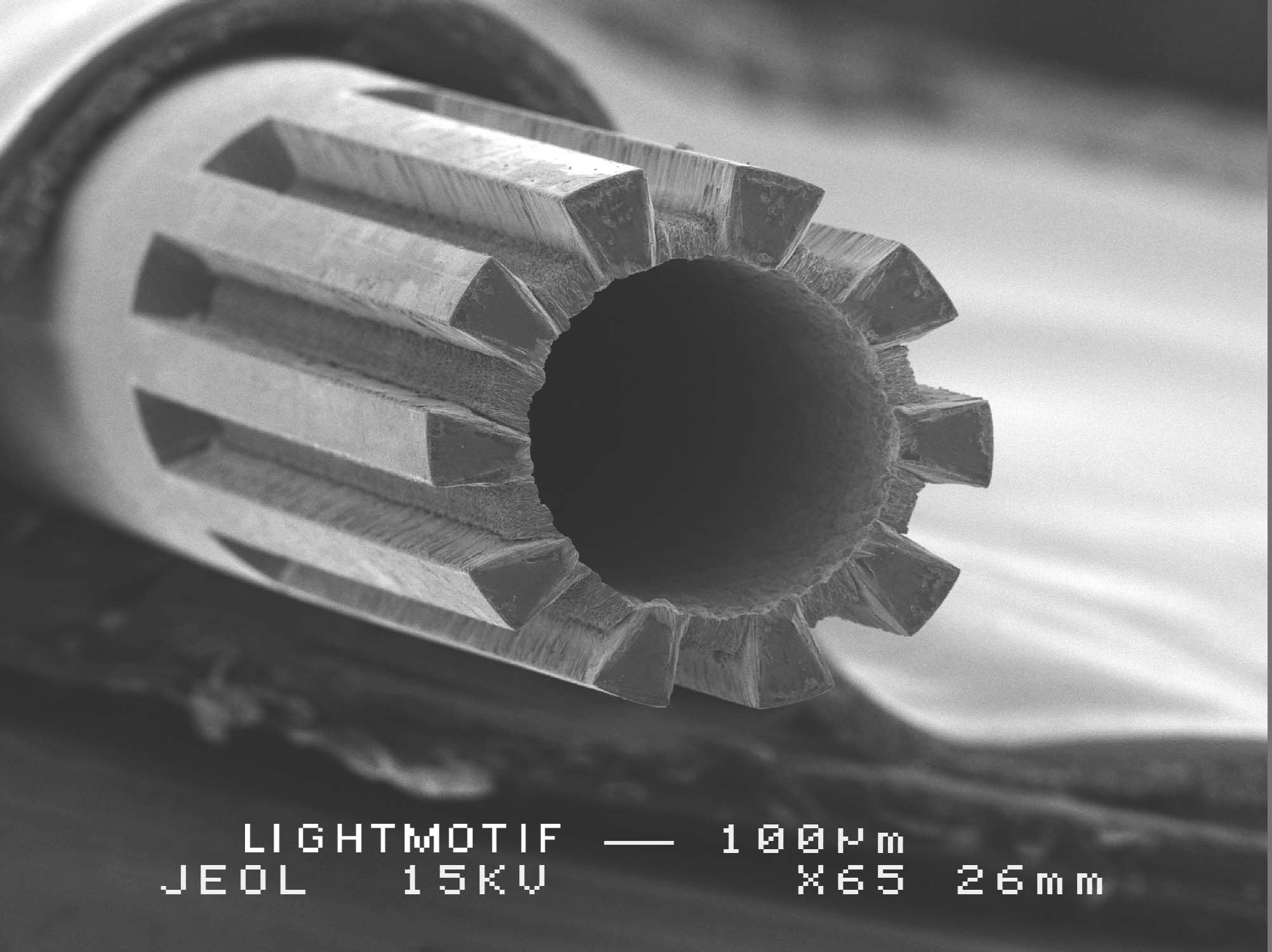

Drilling

Laser drilling using ultrashort pulse lasers allows small holes to be machined with very smooth side walls and without burrs or cracks. Typical material thicknesses range from a couple of micrometers up to a millimeter. Percussion drilling is used for the smallest holes, allowing diameters of up to some tens of micrometers. Machining of larger holes is possible by involving the scan system in the drilling process, e.g., by scanning in circular contours (trepanning).

Laser drilled holes typically show a tapered cross section. This taper can be reduced by a careful selection of the process parameters, but it cannot be fully avoided without using special drilling optics.