Introduction

Lightmotif can assist customers with various micromachining problems, ranging from one-off manufacturing of test/prototype parts or small series production up to complete application development.

Application development

For customers that are investigating a new application we usually start with a quick feasibility study. If the results of this study are promising we can work towards a fully developed application in several iterations of process development, performed in close collaboration with the customer.

Feasibility Studies

Judging the feasibility of a new application is a very important step in the application development process. This step should answer if a solution can be obtained at all, and can give a first estimate of its costs.

The technical and economical feasibility can often only be answered by a hands-on feasibility study. The output of such a study could be a first prototype that the customer can use for initial testing. When planning a feasibility study a careful balance between cost efficiency and completeness has to be made.

Process Development

Processes using an ultrashort pulse laser can be quite complex due to the large amount of parameters that may influence the results. Optimizing a process for speed or quality can be time consuming. Our engineers use extensive knowledge of laser-material interaction, motion and scanning systems, and measurement equipment when working on process research projects. A structured approach, clear goals, and good documentation allow us to get reproducible and usable results efficiently.

Contract manufacturing

For customers who require one-off manufacturing of test/prototype parts, or small series production where investing in a production machine is not viable, contract manufacturing offers a solution. It can also reduce the time to market by bridging the gap between application development and setting up an in-house production system.

Facilities

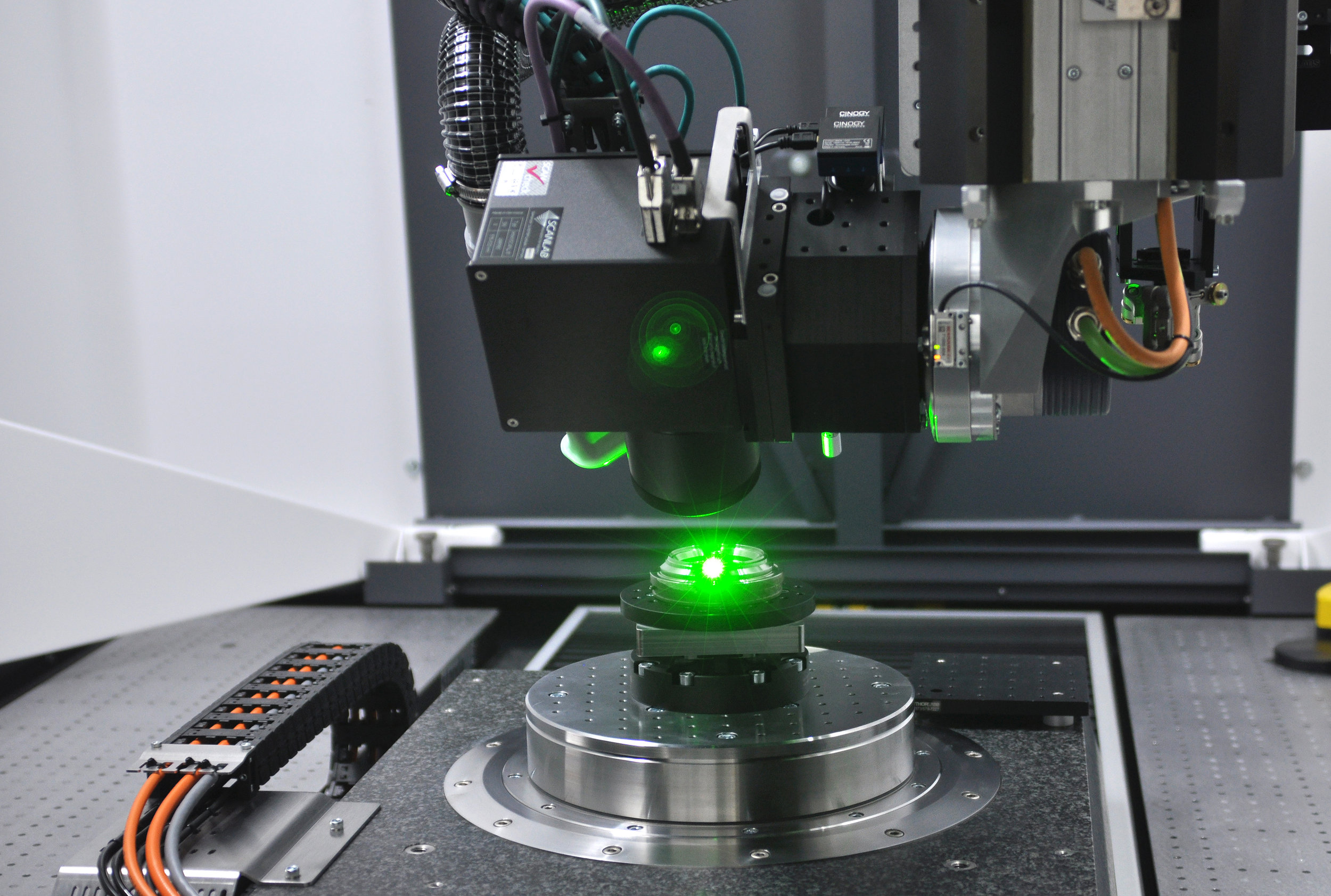

Our applications laboratory / R&D space is housed in a temperature and humidity conditioned room.

We operate a three-axis machine for 2.5D applications (Kern Femto E3) as well as a large custom five-axis system for 3D applications. Both machines use our custom developed laser micromachining control software.

High quality process development requires good measurement equipment. Lightmotif uses optical microscopy, laser scanning confocal microscopy (Olympus LEXT OLS4100), focus-variation microscopy (Alicona InfiniteFocus G5), and scanning electron microscopy for its research and development.