Laser micro-texturing

Laser micro-texturing using ultrashort pulse lasers is a new technology for applying surface textures with very fine features and an extremely high depth resolution. It allows the creation of small-scale textures that change the functional properties of surfaces, like reduction of friction or change of optical properties. The process can be applied on any material and can be used for texturing complex curved surfaces.

Some nice properties / advantages of micro-texturing using ultrashort pulse lasers are:

Machining of extremely small features of down to 10 µm or smaller

Very high depth resolution (sub-micrometer)

Works on nearly every material, including very hard materials

Negligible heat effects: no melt, burrs, or other damage

Contact and force-free process

Texture types

Different types of textures can be distinguished that mainly differ in the way they are made.

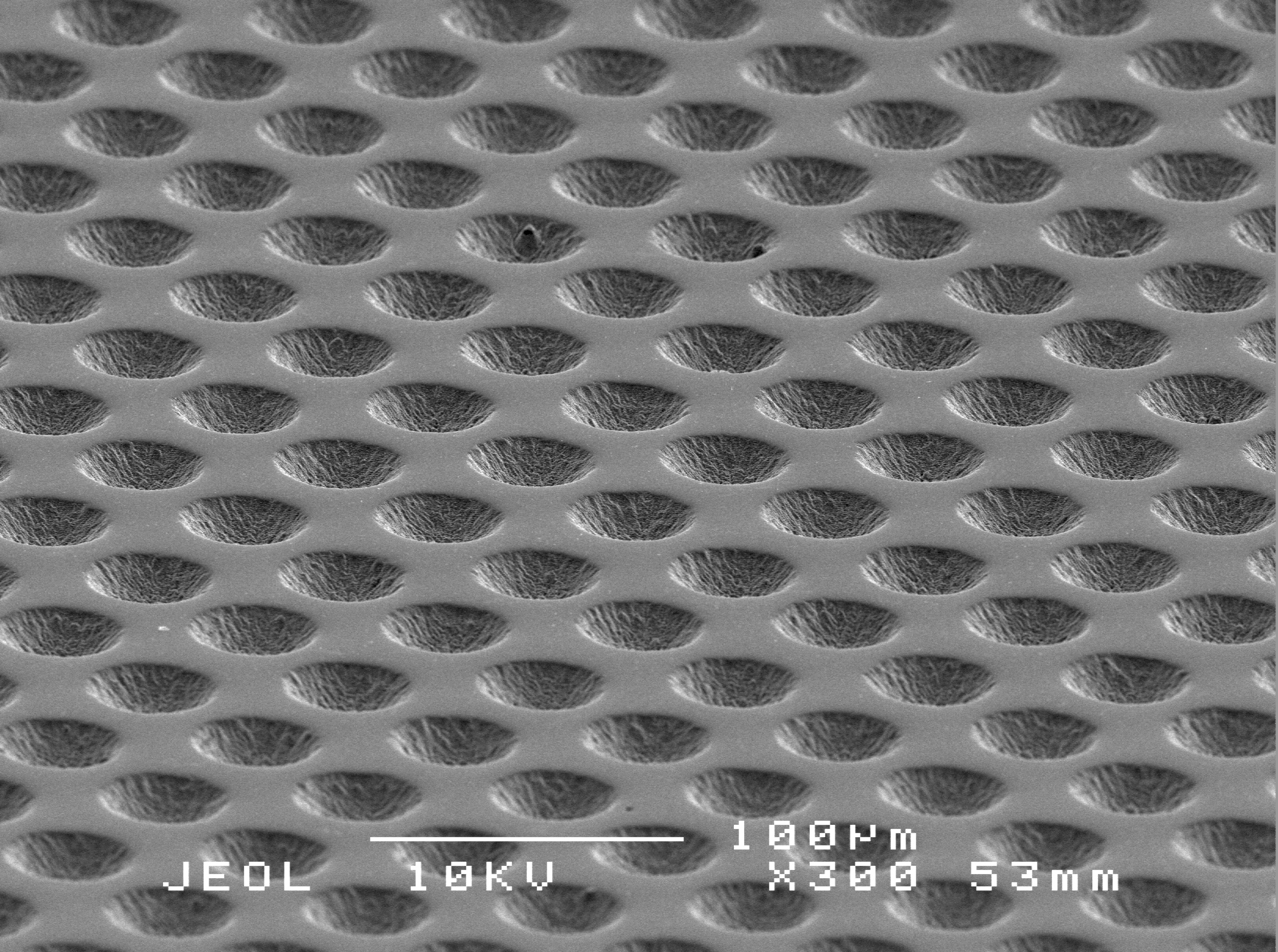

Dimple textures

A dimple texture consists of individual small craters arranged in a certain packing. The dimples can be machined by either keeping the focused laser on one spot and firing a defined amount of pulses (also called percussion drilling), or by moving the spot along a certain path, which can be used to make larger round dimples, or dimples with other shapes.

Free-form textures

Free-form textures can be machined by laser micro-milling, where material is removed layer-by-layer according to a given input model. This method makes it possible to machine any texture, only limited by the size of the focused spot and the depth of a single layer. For typical applications this means a depth resolution of below one micrometer and lateral features smaller than the size of the focused spot.

For this type of texture, the machining time is directly proportional to the depth of the texture. Typical texture depths range from several micrometers to about 0.1 mm, which results in machining rates from some minutes up to one hour per square centimeter.

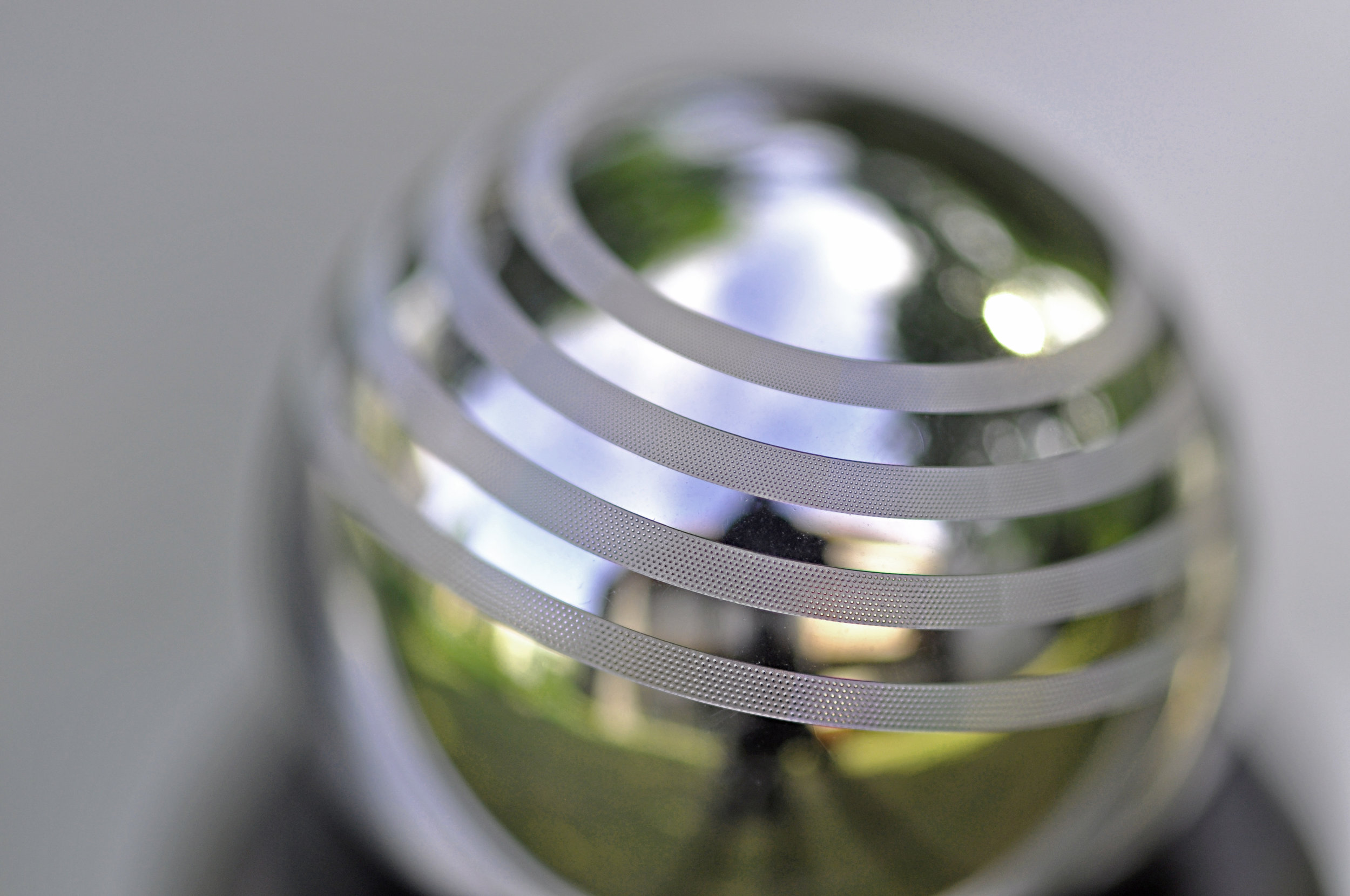

By using texture mapping with a laser micro-milling process, arbitrarily shaped textures can be applied to complex curved surfaces.

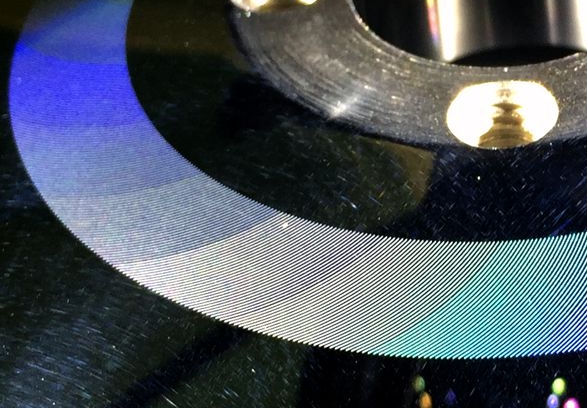

Cross-hatch textures

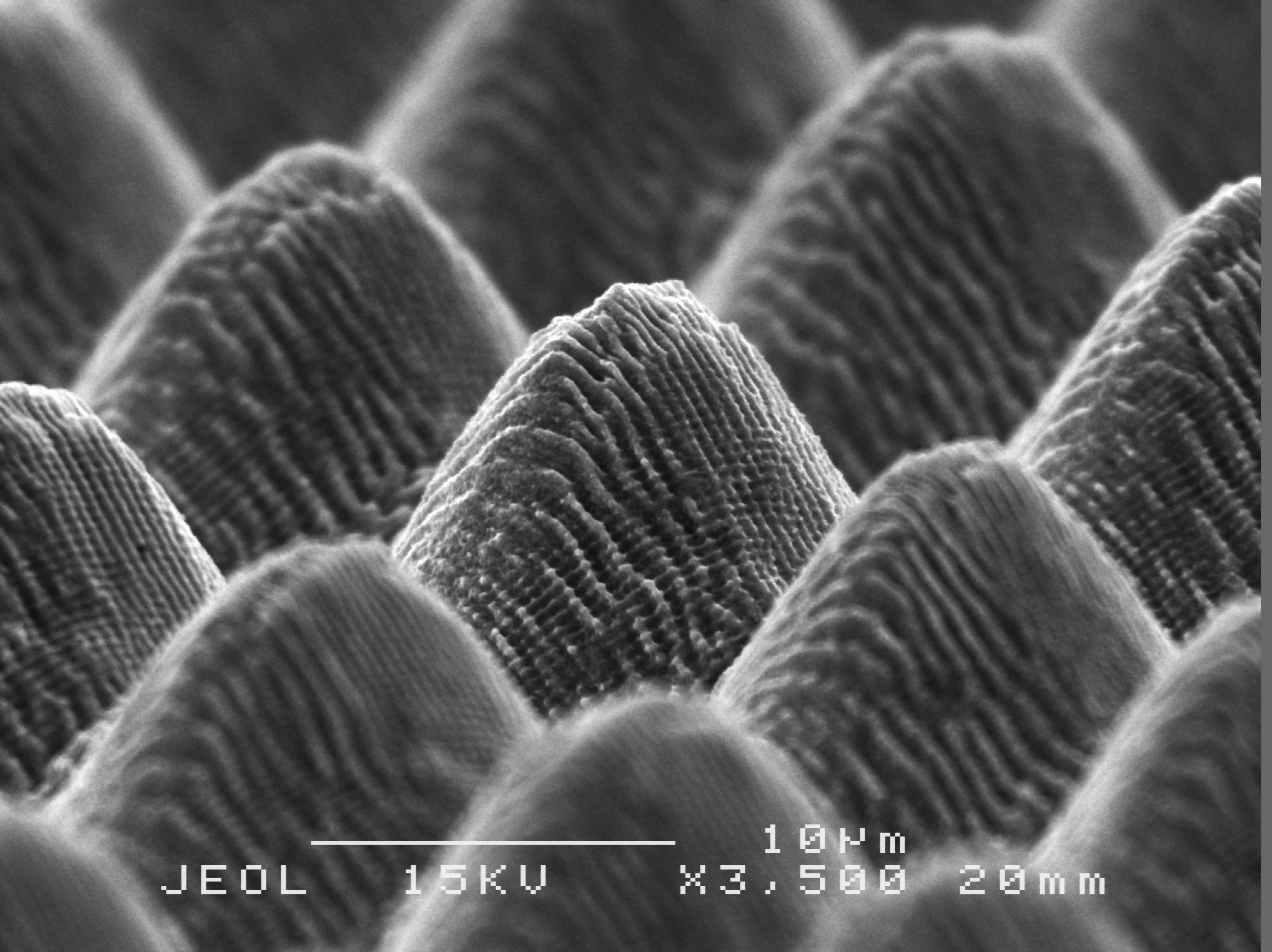

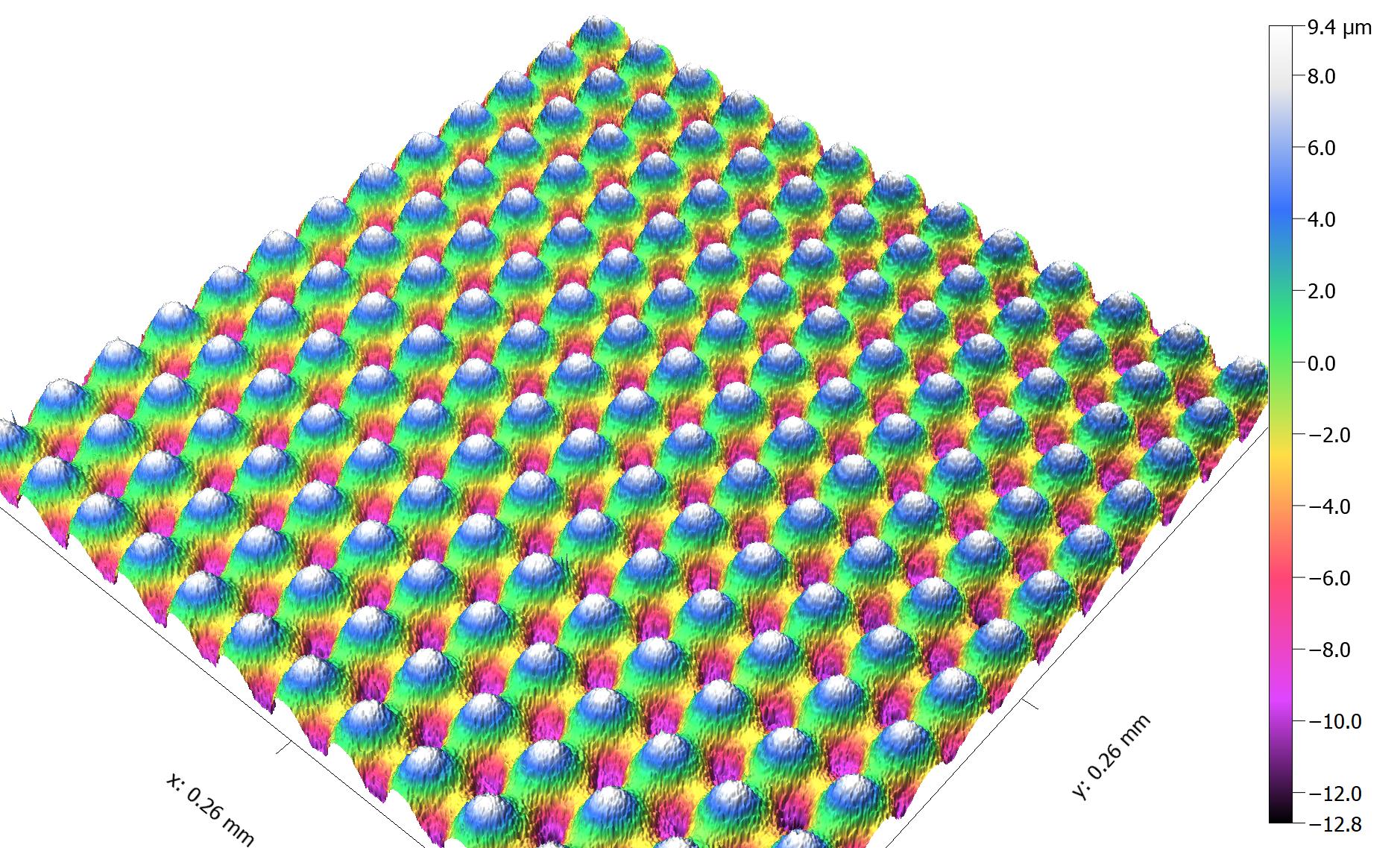

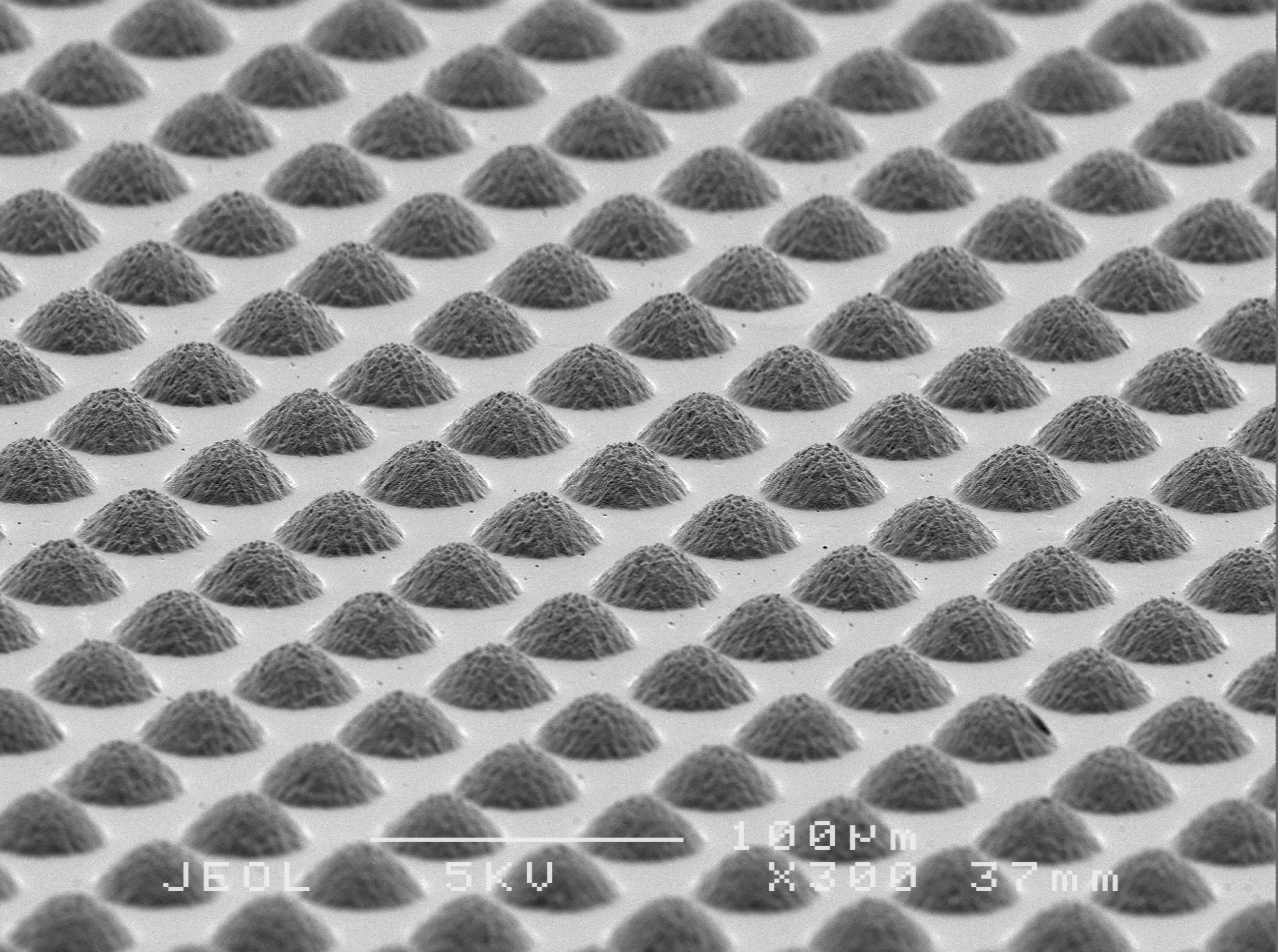

Cross-hatch textures are formed by applying laser machined grooves in a square grid. When placing the grooves at a pitch that is close to the focused spot diameter, a dense pillar texture can be created resembling the shape of an egg box. When the groove pitch is chosen larger, a pattern of square shaped plateaus is obtained.

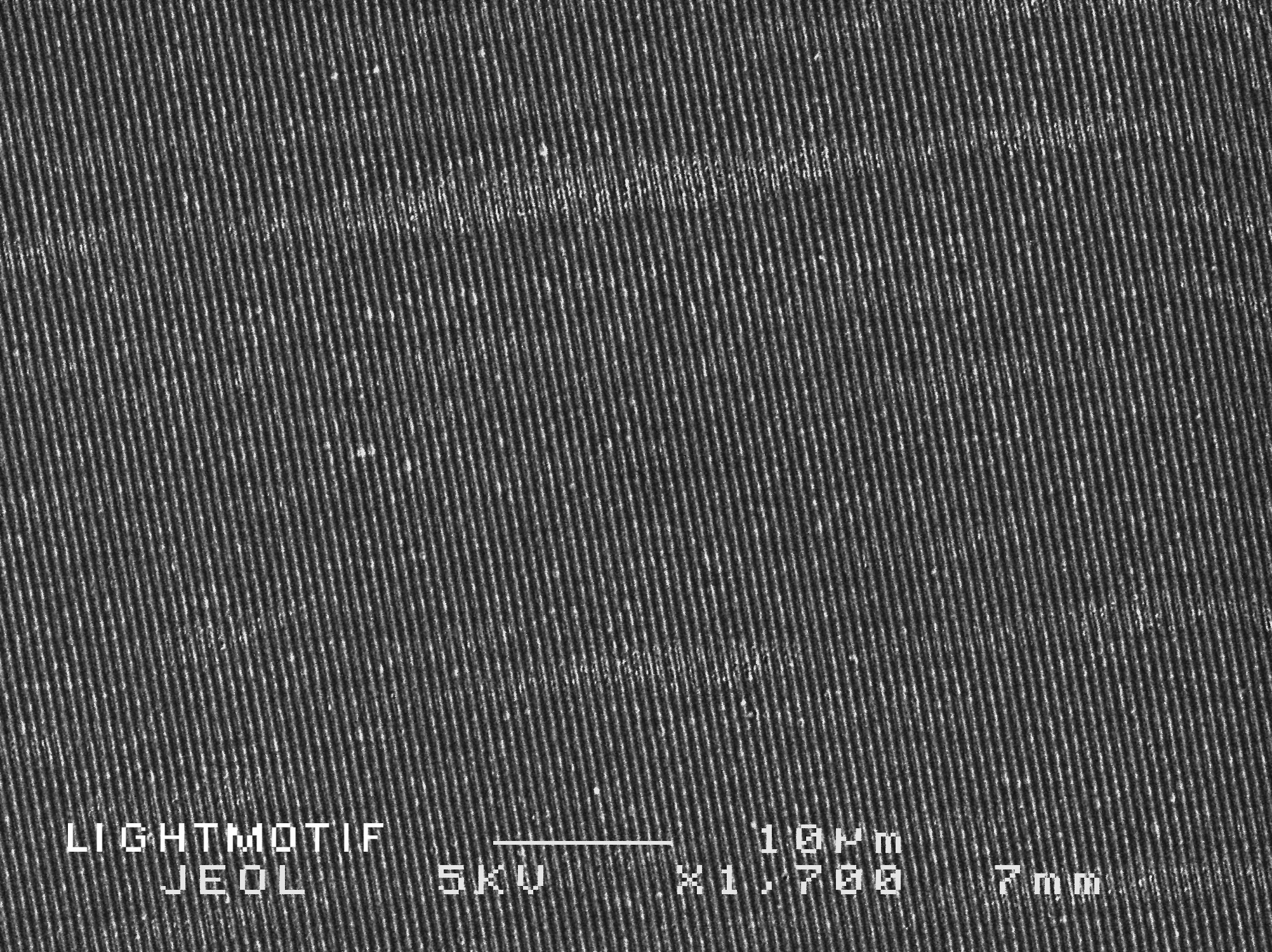

Laser Induced Periodic Surface Structures (LIPSS)

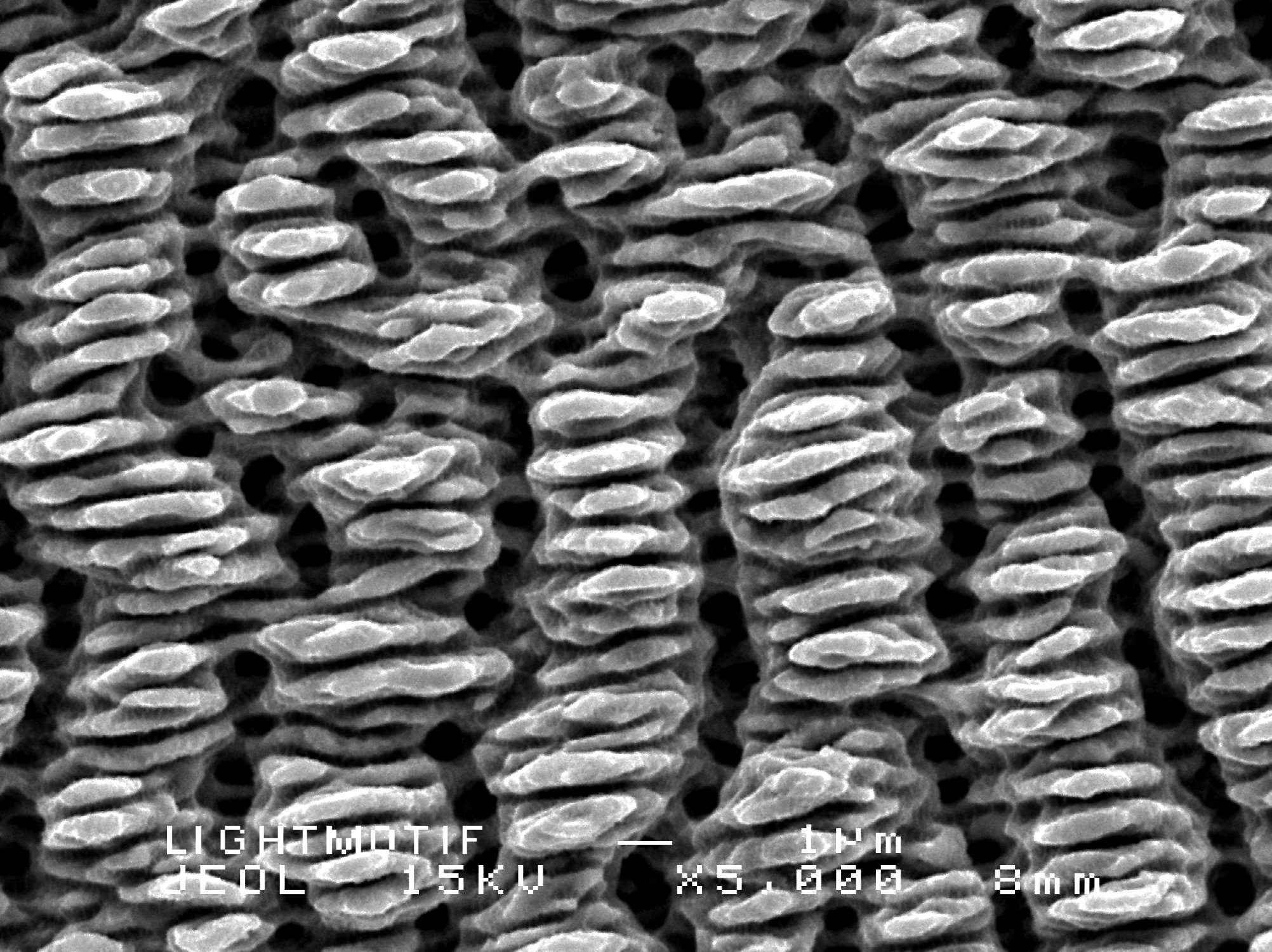

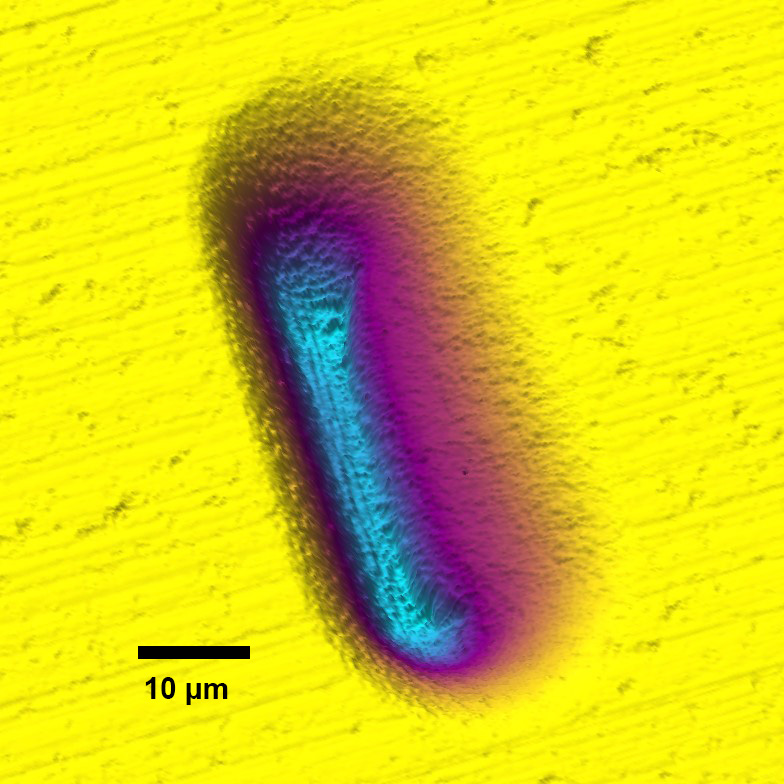

Another interesting effect that is related to the use of ultrashort pulses are self-organizing / laser induced textures. These so-called Laser Induced Periodic Surface Structures (LIPSS) typically form ripple patterns with a pitch in the order of the laser wavelength, resulting in a texture with features that are much smaller than the laser spot.

A sub-micron scale LIPSS texture superimposed on a pillar texture in stainless steel.

Application areas

There are various applications for the types of textures that can be produced using laser micro-texturing:

Decorative textures – Improving the look of parts by adding high definition / low relief textures or LIPSS / color effects to parts

Tribology – Changing frictional properties, e.g., reducing friction on moving parts (seals, bearings) or creating soft-touch consumer or medical parts

Wetting – Making surfaces super-hydrophobic (water repellent) or super-hydrophilic

Optical properties – Altering the surface to reduce glare, change the absorption of light, or even act as a diffraction grating (using LIPSS)

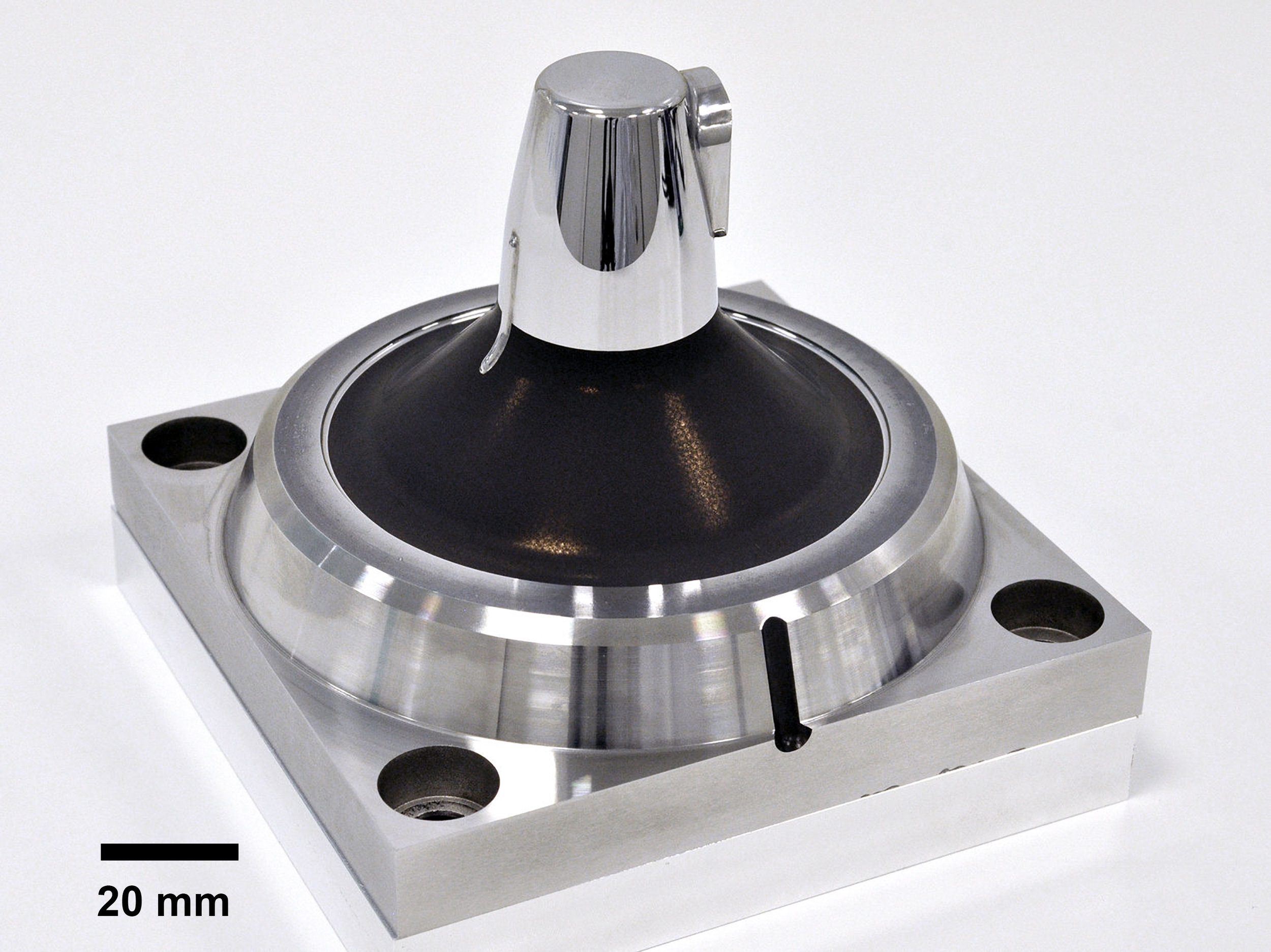

Mold and die texturing

Textures can be directly applied to a part, but it is often more economical to apply them to tools that replicate the negative of the texture by molding, stamping, or similar processes. Laser micro-texturing can be used to apply very fine (functional) textures to the mold surface.

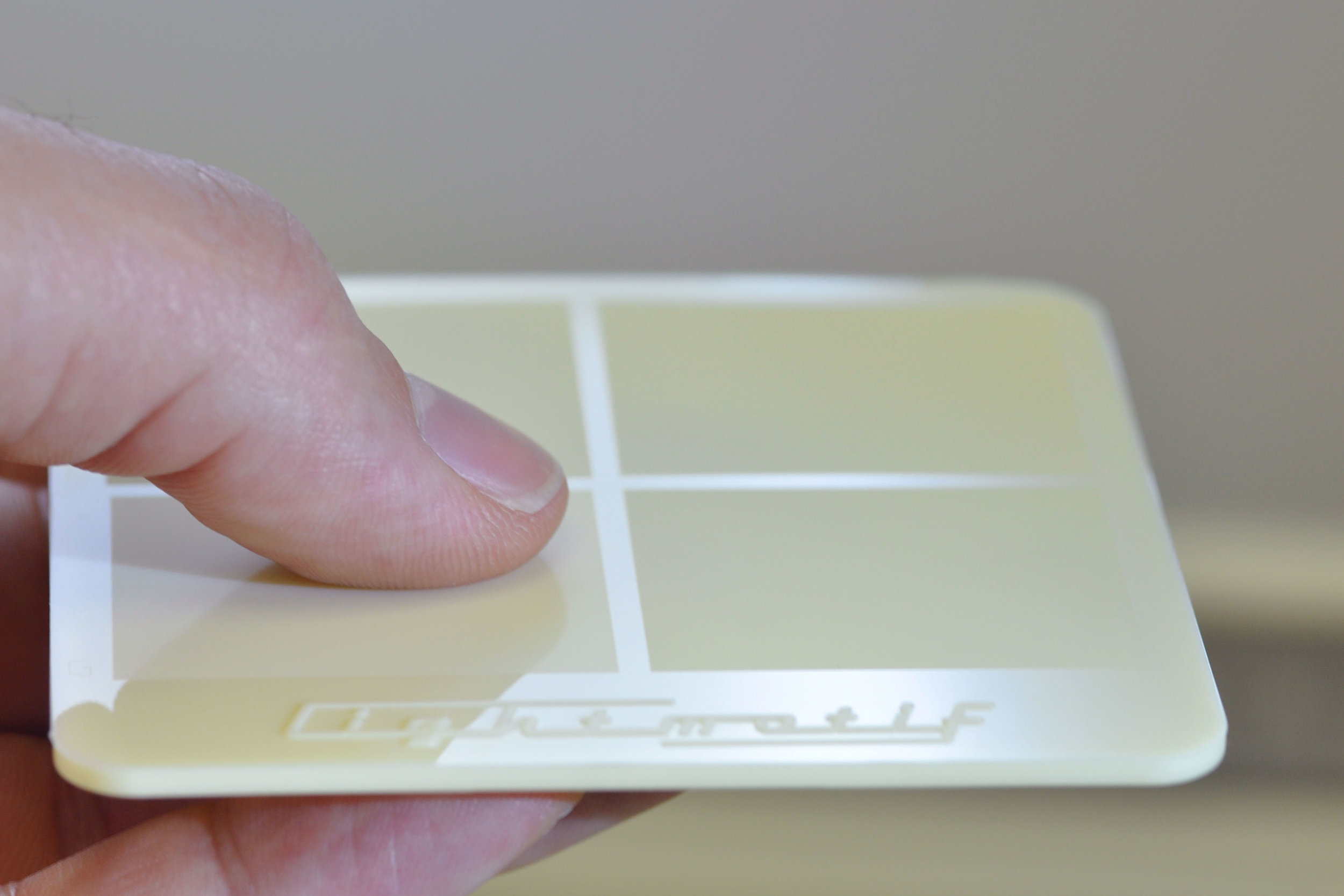

Soft-touch surfaces

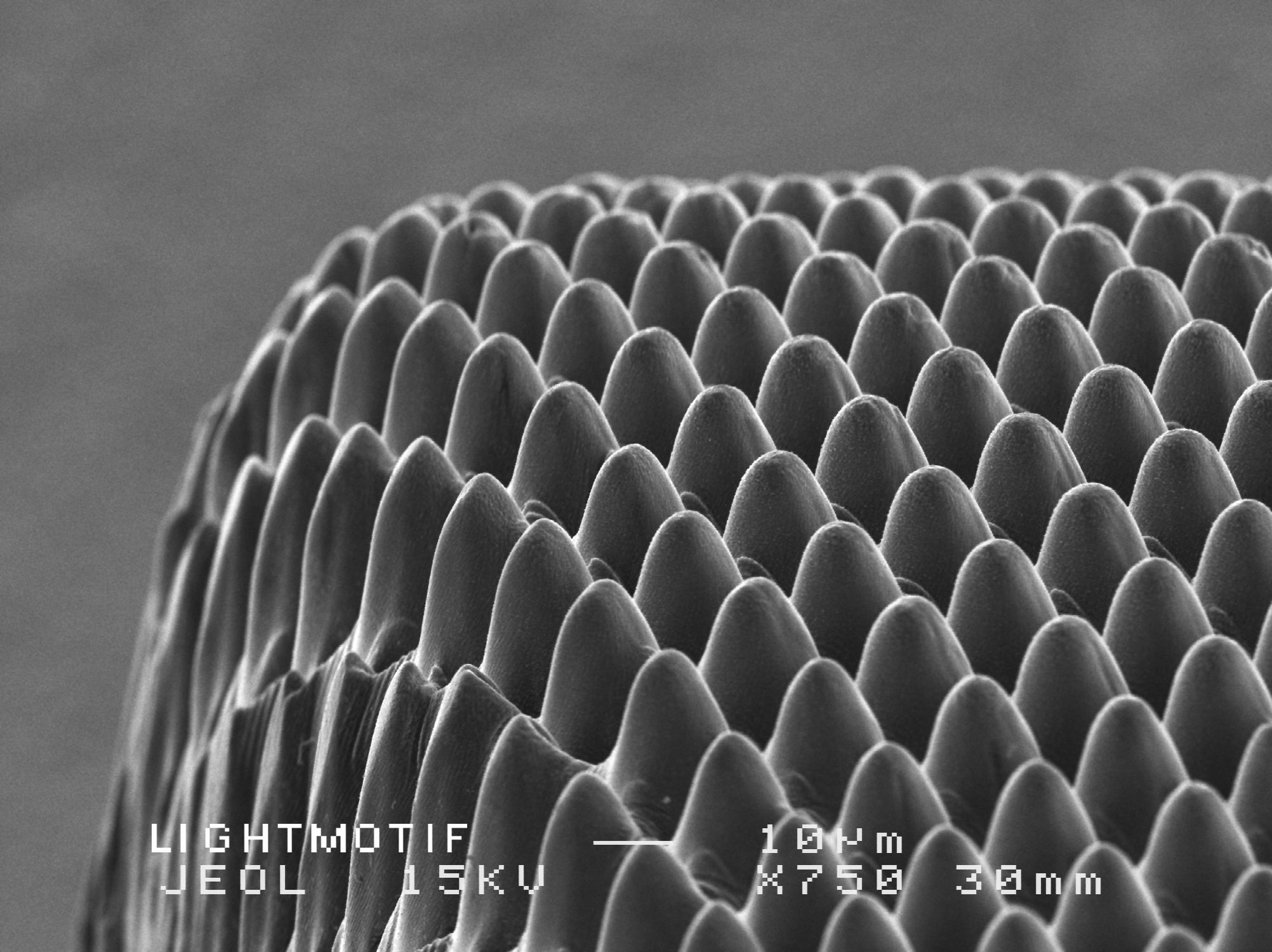

To reduce skin friction a pillar texture can be used, as it reduces the skin contact area and thereby the friction. The result is a surface with a high quality / soft feel (and reduced glare).

Friction reduction

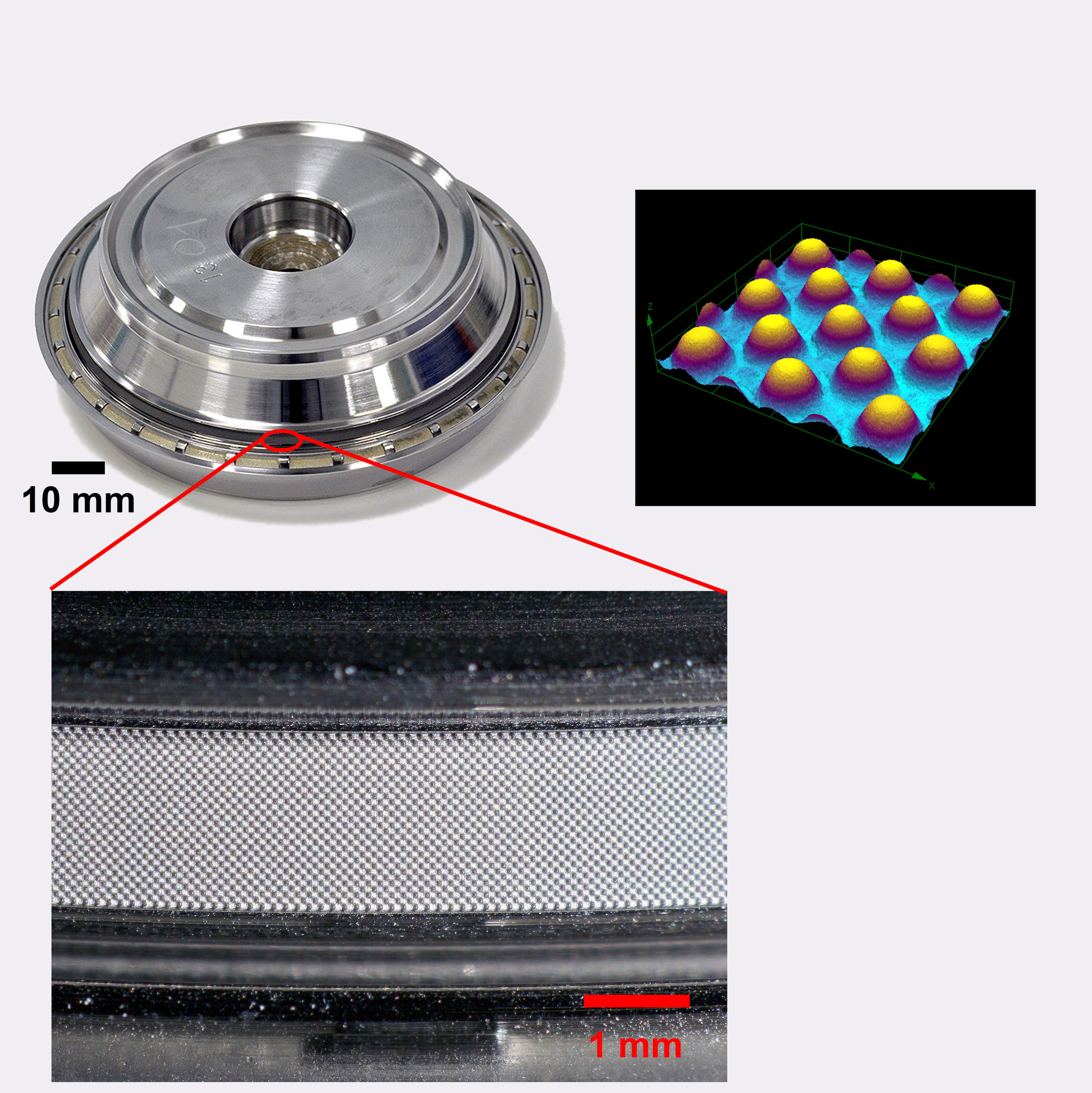

Dimple textures can be used to reduce lubricated friction, where each individual dimple / pocket creates a hydrodynamic pressure and acts as a reservoir for the lubricant.

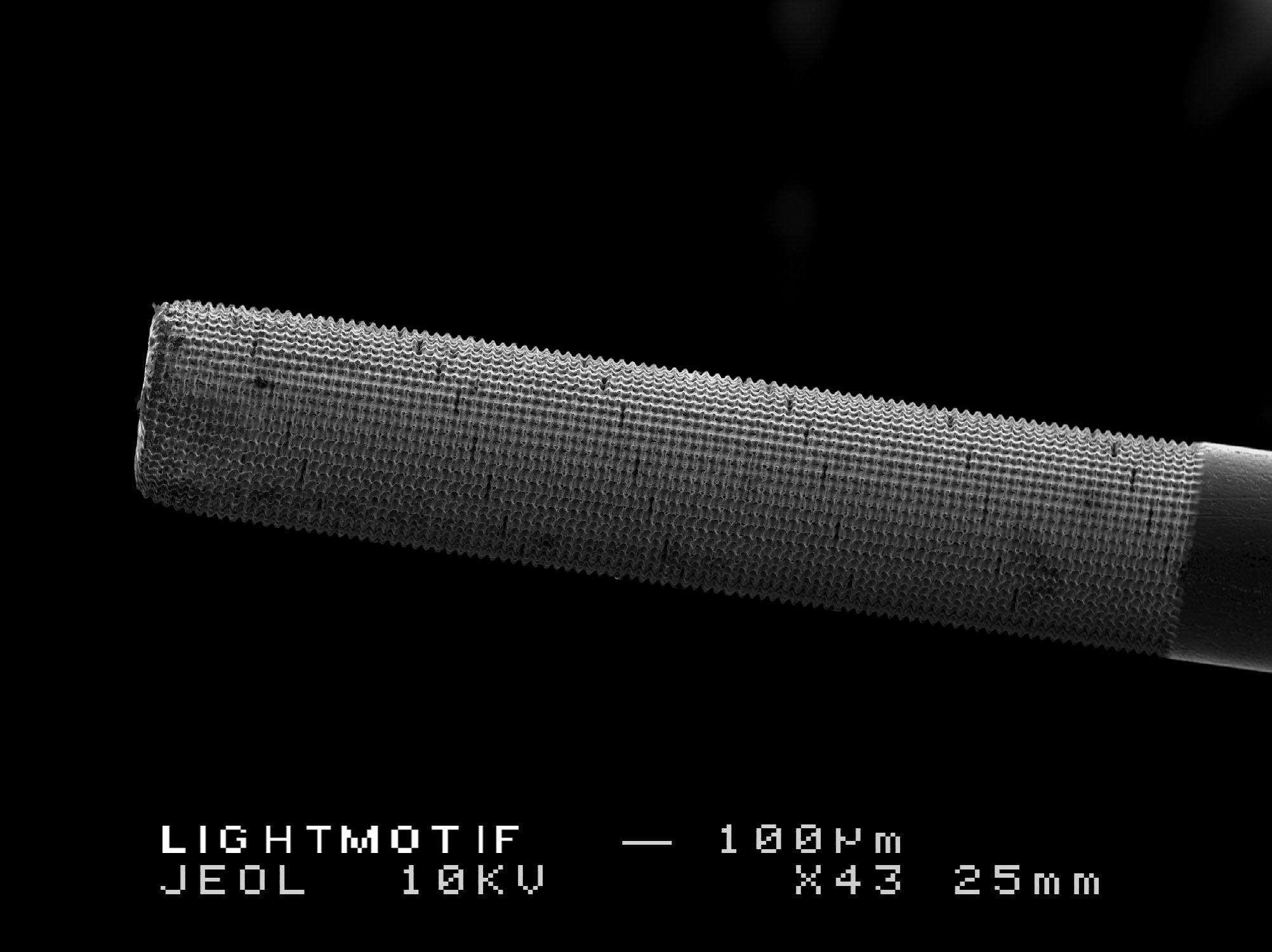

An example of a dimple texture applied to a tool: the curved flute surface of a drill is machined with a texture consisting of oblong shaped dimples with a non-symmetrical cross section. This drill was machined as demonstrator within the EU funded ADALAM project.

A 30 mm diameter steel sphere machined to a depth of 20 μm, leaving a pattern of unmachined disks.

Decorative finish

Textures can be used to create a decorative finish on steel parts, e.g., for use in jewelry or for creating attractive molded parts (when used in a mold).